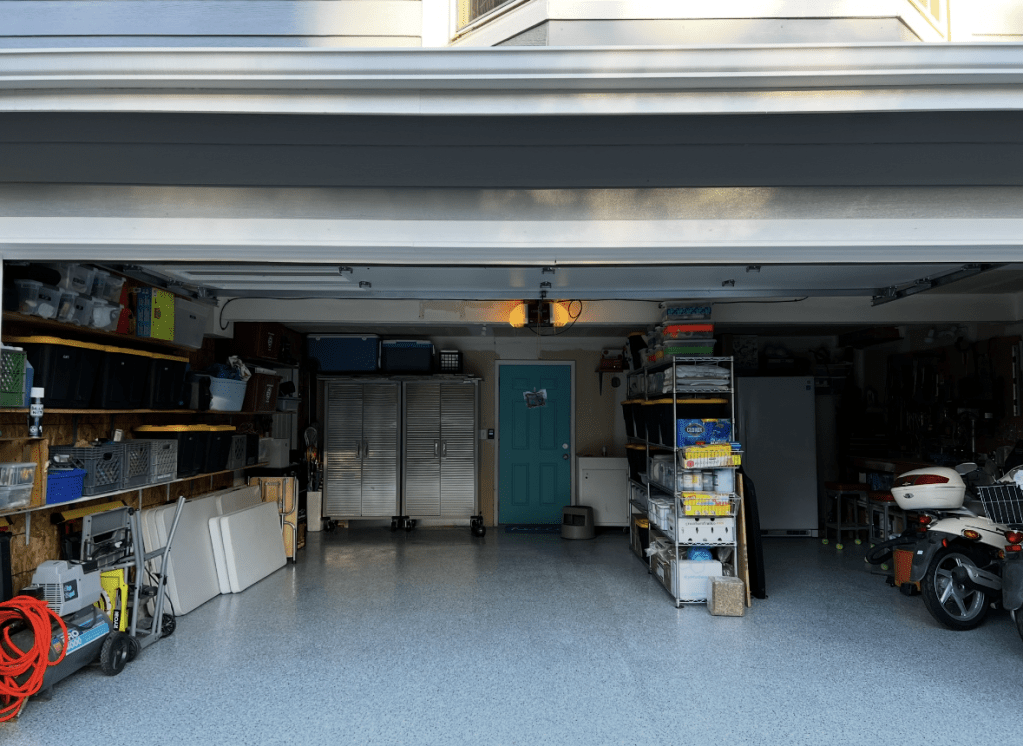

ReInvigorate Spaces

protect from stains and cracks

The process

Concrete is prepped using industrial diamond grinding equipment, cleaned thoroughly, and coated with tri-system, top quality polyaspartic.

Polyaspartic is significantly more durable, scratch resistant, and non-yellowing when compared to typical epoxy coatings.

How it works

The tri-system coating consists of three layers:

- Base layer

- a base coat of colored polyaspartic that bonds to prepped concrete

- creates moisture barrier for confidence against peeling

- builds a consistent underlying base color

- Broad Flake

- consistent and even broadcasting of color chips for uniform color

- choose from timeless trusted color schemes, or customize your own

- provides anti-slip texture while maintaining a smooth finish

- Top Coat Seal

- a clear coat of polyaspartic to lock in the flakes and evenly finish the space

- UV stable means no yellowing over time

- 4x stronger than traditional epoxy means no issues from scratching/heavy vehicle use